Several of you have been asking for a solution that allows the exhaust servo to be removed/discarded. Not so much for the weight reduction, but for the space savings.

Well, here ya go...

I took up the project a couple days ago, after having a look at the signals involved, with my trusty old-school o-scope. Turns out the signals between the ECM and the servo are somewhat more involved than one might imagine. While it's not exactly straight forward, it turned out to be a fairly simple task. I decided to use an inexpensive PIC microcontroller (a single chip computer). With space savings the primary objective, I went for a small footprint package, and used an 8-pin PIC12F683.

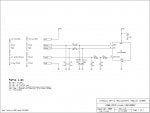

For those that are interested in making their own, and have the materials & ability, I've attached;

- A schematic for the circuit

- The PIC micro assembler language source code

- A couple pictures of my assembled prototype (to give you an idea what's possible)

I just finished a fairly thorough series of tests (on the tread mill in my garage). Although I have yet to do some real-world tests, out on the track (darn snow), I'm confident the design is solid.

The finished circuit could be made much smaller (maybe %50) by using SMT components, and a custom PCB. But, I think this is "small" enough.

There are those who will wonder "What is the benefit of this mod"?... Simply put - space savings. For those building track-only bikes, and are cramped for space, this is the ticket.

I can foresee no reason that there will be any performance improvement. For the normal street rider, this would be a waste of time (unless you need the space of course).

This was designed specifically for the 2008 - 2010 CBR1000RR. It may work on other models & years, but I haven't tested it. The design is general enough that it should work on other bikes, tho. If you test it on other makes/models/years, and find it works, let me know. Or, if you find the design needs to be altered to accommodate others, let me know that too.

Note: The source code provided here is licensed under the GPL. Use it as you will. I expect anyone that produces replicas based on this code (or derivatives there-of), either commercially or otherwise, to provide a copy of the source code (or access to it) and a copy of the schematic, to anyone they supply it to.

Edit 12/22/2009: Currently researching the feasibility of making a bunch of these. See post #24 below.

Edit 12/27/2009: I believe I've located a source for the OEM connector for the 2008-2010, as well as the older 2004-2007 models, thus making it possible to build a plug&play solution. Also in the process of locating someone locally, with an 04-07, to do some tests (it should work as-is, just need to do some sanity checks).

Well, here ya go...

I took up the project a couple days ago, after having a look at the signals involved, with my trusty old-school o-scope. Turns out the signals between the ECM and the servo are somewhat more involved than one might imagine. While it's not exactly straight forward, it turned out to be a fairly simple task. I decided to use an inexpensive PIC microcontroller (a single chip computer). With space savings the primary objective, I went for a small footprint package, and used an 8-pin PIC12F683.

For those that are interested in making their own, and have the materials & ability, I've attached;

- A schematic for the circuit

- The PIC micro assembler language source code

- A couple pictures of my assembled prototype (to give you an idea what's possible)

I just finished a fairly thorough series of tests (on the tread mill in my garage). Although I have yet to do some real-world tests, out on the track (darn snow), I'm confident the design is solid.

The finished circuit could be made much smaller (maybe %50) by using SMT components, and a custom PCB. But, I think this is "small" enough.

There are those who will wonder "What is the benefit of this mod"?... Simply put - space savings. For those building track-only bikes, and are cramped for space, this is the ticket.

I can foresee no reason that there will be any performance improvement. For the normal street rider, this would be a waste of time (unless you need the space of course).

This was designed specifically for the 2008 - 2010 CBR1000RR. It may work on other models & years, but I haven't tested it. The design is general enough that it should work on other bikes, tho. If you test it on other makes/models/years, and find it works, let me know. Or, if you find the design needs to be altered to accommodate others, let me know that too.

Note: The source code provided here is licensed under the GPL. Use it as you will. I expect anyone that produces replicas based on this code (or derivatives there-of), either commercially or otherwise, to provide a copy of the source code (or access to it) and a copy of the schematic, to anyone they supply it to.

Edit 12/22/2009: Currently researching the feasibility of making a bunch of these. See post #24 below.

Edit 12/27/2009: I believe I've located a source for the OEM connector for the 2008-2010, as well as the older 2004-2007 models, thus making it possible to build a plug&play solution. Also in the process of locating someone locally, with an 04-07, to do some tests (it should work as-is, just need to do some sanity checks).